HI-GRADE

SYNGAS R&DClean Energy for a Clean Earth

HiPoint plans to utilize biomass, green waste, horse waste, and even plastic bags to produce High-Grade Syngas converted to electricity, reducing utility costs and off-grid operations. Collaborating with local energy companies, HiPoint aims to establish long offtake agreements and distribute natural energy to charging stations, creating e-RINS, Carbon Tax Credits, and profitable incentives.

Hi-GRADE SYNGAS (R&D)

Clean Energy for a Clean EarthHiPoint plans to utilize biomass, green waste, horse waste, and even plastic bags to produce Hi-Grade Syngas converted to electricity, reducing utility costs and off-grid operations. Collaborating with local energy companies, HiPoint aims to establish long offtake agreements and distribute natural energy to charging stations, creating e-RINS, Carbon Tax Credits, and profitable incentives.

Hi-GRADE SYNGAS

Manufactured locally in agriculture for agriculture.

Hi-Grade Syngas

Biomass to Energy for a self-sustaining planet

What is Syngas?

Syngas, the mixture of CO and H2 that results from all the reactions discussed so far, can be used directly as fuel. Using the HiPoint Energy system in conjunction with Green Fortress Engineering, the feedstock is reduced to pure CO and H2, producing High-Grade Syngas. Further R&D and the use of membranes can further process Syngas to hydrogen for fuel cells on farms, in underdeveloped villages or as secondary redundancy in hospitals.

What is Syngas?

Syngas, the mixture of CO and H2 that results from all the reactions discussed so far, can be used directly as fuel. Using the HiPoint Energy system in conjunction with Green Fortress Engineering, the feedstock is reduced to pure CO and H2, producing High-Grade Syngas. Further R&D and the use of membranes can further process Syngas to hydrogen for fuel cells on farms, in underdeveloped villages or as secondary redundancy in hospitals.

Next-Gen Syngas

Our collaboration uses a multi-patented process to convert biomass into chemicals, energy fuel, and heat by increasing the energy content and separating gases from ash and biochar without oil build-up. The process can be customized to maximize gas output to reduce utility costs. The vision is to scale up in developing countries to power a site or village. Future R&D will further process the Syngas, convert it into hydrogen, and store it for reuse in various applications at cost-effective prices.

Patent Pending Innovation.

Next-Gen Syngas

Patent Pending Innovation.

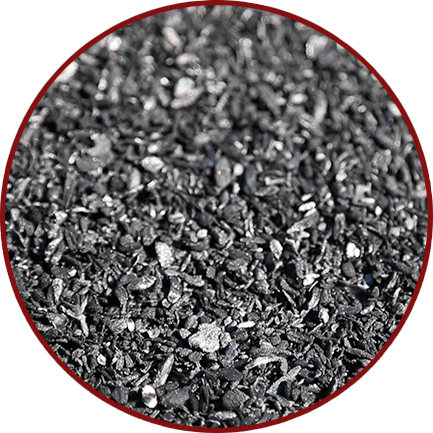

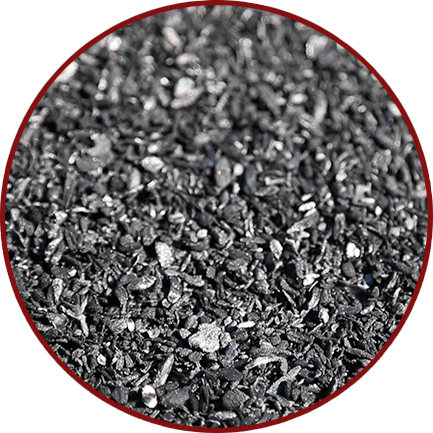

Non- Labile (Persistent) Biochar

We produce biochar by heating biomass at very high temperatures and low moisture levels. We use horse stall residual waste; however, we can also use corn stover, hemp flour, and green waste. Plus, a small percentage of plastic horse bags can be added. By adjusting moisture levels, we can create 20% biochar output. Our biochar is chemical-free and ash-free, making it safe to add to HiPoints organic matter Biofertilizer. The result is an increase in soil fertility and nutrient availability. Biochar is also helpful in removing contaminants and mitigating drought, making it valuable for waste management and wastewater treatment.

Non-Labile (Persistent) Biochar

We produce biochar by heating biomass at very high temperatures and low moisture levels. We use horse stall residual waste; however, we can also use corn stover, hemp flour, and green waste. Plus, a small percentage of plastic horse bags can be added. By adjusting moisture levels, we can create 20% biochar output. Our biochar is chemical-free and ash-free, making it safe to add to HiPoints organic matter Biofertilizer. The result is an increase in soil fertility and nutrient availability. Biochar is also helpful in removing contaminants and mitigating drought, making it valuable for waste management and wastewater treatment.

Pure. Syngas. Biochar.

OREGON R&D FACILITY

With our pending R&D project in Oregon, this is the latest collaboration between HiPoint Energy, Green Fortress Engineering and AgriPower to use biomass as a resource to create high-grade tar-free syngas to electricity to the grid and non-labile biochar for our fertilizers at commercially viable prices. Using a dry, abundant feedstock that is currently being inadequately disposed of, HiPoint Energy, Green Fortress Engineering, and AgriPower can do their part to support sustainability.

OREGON R&D FACILITY

With our pending R&D project in Oregon, this is the latest of HiPoint's collaboration with Green Fortress Engineering and AgriPower to use biomass as a resource to create hi-grade tar-free syngas to electricity to the grid and non-labile biochar for our fertilizers at commercially viable prices. Using a dry, abundant feedstock that is currently being inadequately disposed of, HiPoint Energy, Green Fortress Engineering, and AgriPower can do their part to support environmental sustainability.

HiPoint Energy Process

The multi-patented process converts biomass into chemicals, energy fuel, and heat. We achieve this by increasing the energy content to the syngas and separating the gases from ash & biochar through high temperatures under oxygen-deprived conditions. We are able to modulate the balance of biochar and syngas to achieve the desired output. Dry feedstock produces excess carbon char, while moderate moisture maximizes hydrogen production and electrical power. Users can customize the system's operation to suit their needs.