HPE Biofuel

Clean Green Energy for a Clean Green Planet

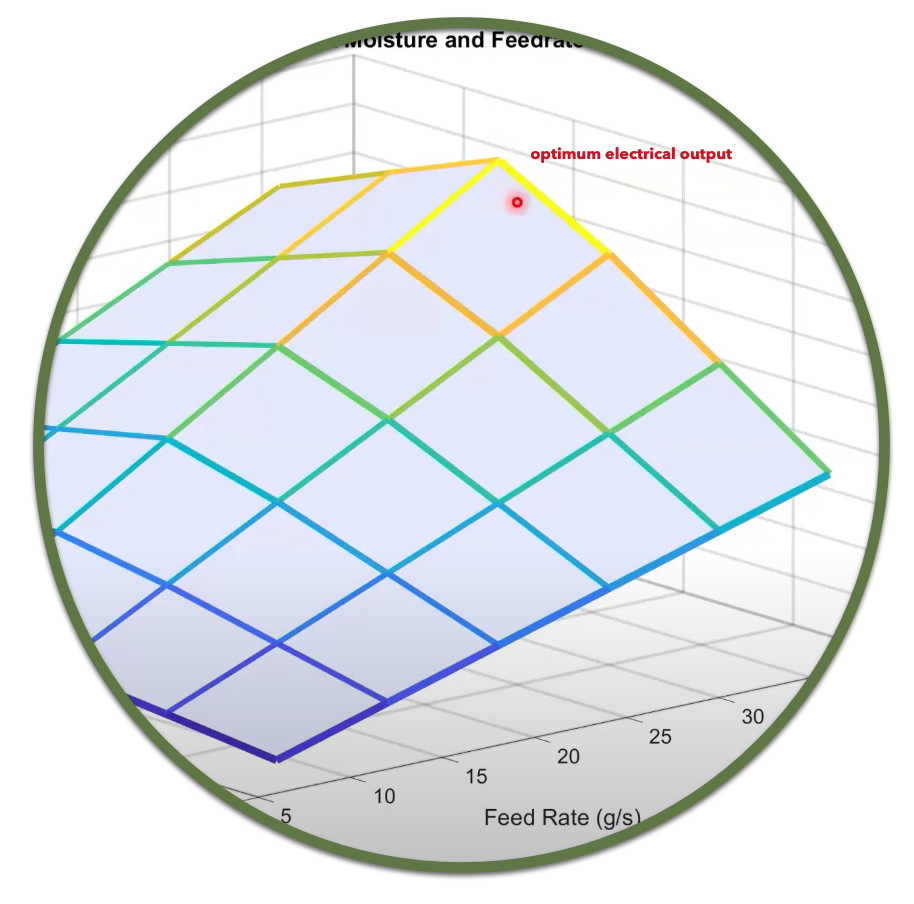

The primary output of HiPoint Energy units is the premium alternative fuels, in the form of either Syngas or alt-diesel, to be converted into electric power. The fuels will power the unit and will be sold through long-term offtake agreements by distributing to charging stations, creating e-RINS, Carbon Tax Credits, and profitable incentives.

What is Alt-fuels

Next-Gen Electric Power

Uses for Alt-Fuels

Competitive Advantage

Our system is designed to stand out due to its unique combination of efficient alternative fuel production for electric power and tar-free operation. Our system also excels in several ways. It provides more efficient, higher-grade production with higher energy content, suitable for regional deployment. Operating at a known temperature of around 950°c ensures cleaner, tar-free separation and flare-free operation. Additionally, it can extract a stream of 99.5% pure hydrogen while retaining sufficient syngas energy content to self-power the all-electric conversion system.

We use a portable Bi-Modular Reactor system to create cleaner and more lucrative on-site energy than our competition. This can help reduce the damaging effects of climate change in rural areas.