Process

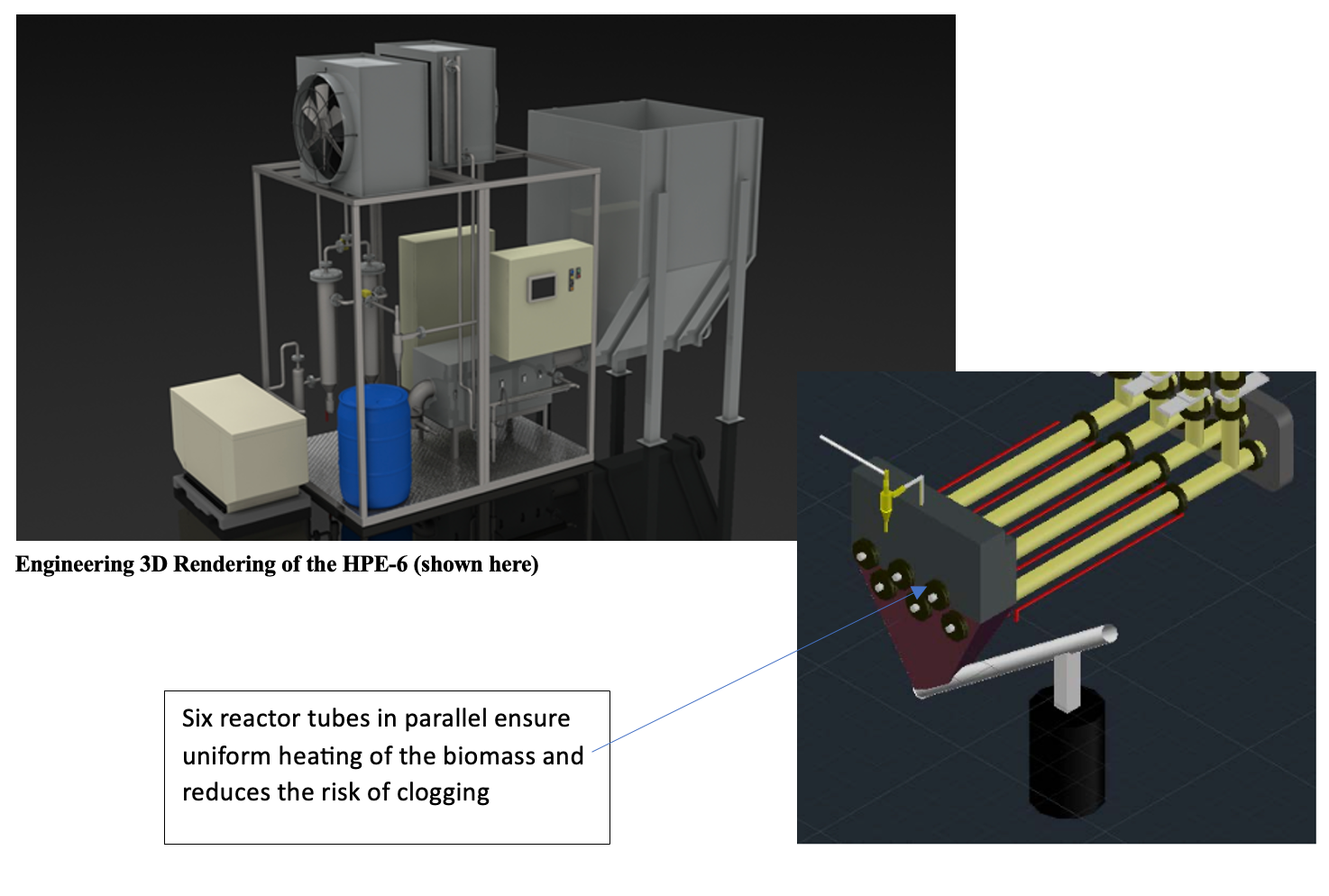

Indirectly Heated Pyrolytic GasificationThe beta unit owned by the University of Indiana, which is the basis for the HPe-6 system, converts green waste into syngas, a type of biofuel made through partial combustion. The process involves converting organic matter, such as wood chips or agricultural waste, into a combustible gas called syngas. Our engineers will design a commercial unit capable of producing either high-yield syngas or biodiesel to be used to power local utilities and output electricity to the grid. The process is considered clean because it produces minimal air pollution and greenhouse gas emissions compared to traditional fossil fuel-based power generation.

Process

The beta unit owned by the University of Indiana, which is the basis for the HPe-6 system, converts green waste into syngas, a type of biofuel made through partial combustion. The process involves converting organic matter, such as wood chips or agricultural waste, into a combustible gas called syngas. Our engineers will design a commercial unit capable of producing either high-yield syngas or biodiesel to be used to power local utilities and output electricity to the grid. The process is considered clean because it produces minimal air pollution and greenhouse gas emissions compared to traditional fossil fuel-based power generation.

Feedstock

The ideal feedstock is plant-based lignocellulosic (woody) material such as agricultural residue, landscape trimmings, cardboard, and non-halogenated plastics. By integrating these innovations, the feedstock mix can be suitable for warehouses, office buildings, farm operations, forward operating bases, and remote facilities. HPE is creating a commercial biomass conversion system producing syngas or biodiesel, hydrogen, and biochar that offers a more efficient, flexible, and scalable solution for producing valuable chemicals, fuels, heat, and electric power from organic matter at a lower price.

Feedstock

HPE is adapting an innovative biomass conversion system that transforms organic matter into valuable by-products. The technology stands out from existing solutions due to a new technique called Indirectly- Heated Pyrolytic Gasification. This high-temperature process cracks all complex hydrocarbons into their simplest components to produce a high-hydrogen syngas plus a pure carbon biochar residue. The syngas or biodiesel can be used as a fuel to generate electricity. It can also be fed through a membrane separation unit to extract a portion of the hydrogen. Because the technology is energy self-sufficient when provided a steady input of feedstock, this “green” hydrogen is radically less expensive than competing methods.

- Efficient Syngas Production: Our system utilizes a "plug flow" process, ensuring consistent energy content and minimizing gas leakage.

- Tar-Free Operation: High-temperature separation of gases and ash/biochar enables efficient and clean production.

- Enhanced Syngas Production: An improved gasification pyrolysis process results in higher energy content, syngas production, and cleaner output.

- Flexible Output: Users can adjust feedstock drying to balance biochar and energy production, maximizing revenue or meeting specific needs.

- Scalability: Our technology can be scaled up for various markets, from individual operators to utility grid-connected baseload generation systems with an array of HPe-6 units to generate 2MW of continuous, carbon-neutral power for delivery to the utility grid.

- Improved Process Efficiency: Multiple innovations enhance the conversion process, making it more efficient and effective.

HPE is adapting an innovative biomass conversion system that transforms organic matter into valuable by-products. The technology stands out from existing solutions due to a new technique called Indirectly- Heated Pyrolytic Gasification. This high-temperature process cracks all complex hydrocarbons into their simplest components to produce a high-hydrogen syngas plus a pure carbon biochar residue. The syngas or biodiesel can be used as a fuel to generate electricity. It can also be fed through a membrane separation unit to extract a portion of the hydrogen. Because the technology is energy self-sufficient when provided a steady input of feedstock, this “green” hydrogen is radically less expensive than competing methods.

- Efficient Syngas Production: Our system utilizes a "plug flow" process, ensuring consistent energy content and minimizing gas leakage.

- Tar-Free Operation: High-temperature separation of gases and ash/biochar enables efficient and clean production.

- Enhanced Syngas Production: Improved gasification/pyrolysis process and syngas production result in higher energy content and cleaner output.

- Flexible Output: Users can adjust feedstock drying to balance biochar and energy production, maximizing revenue or meeting specific needs.

- Scalability: Our technology can be scaled up for various markets, from individual operators to utility grid-connected baseload generation systems with an array of HPE06 units to generate 2MW of continuous, carbon-neutral power for delivery to the utility grid.

- Improved Process Efficiency: Multiple innovations enhance the conversion process, making it more efficient and effective.

Volume

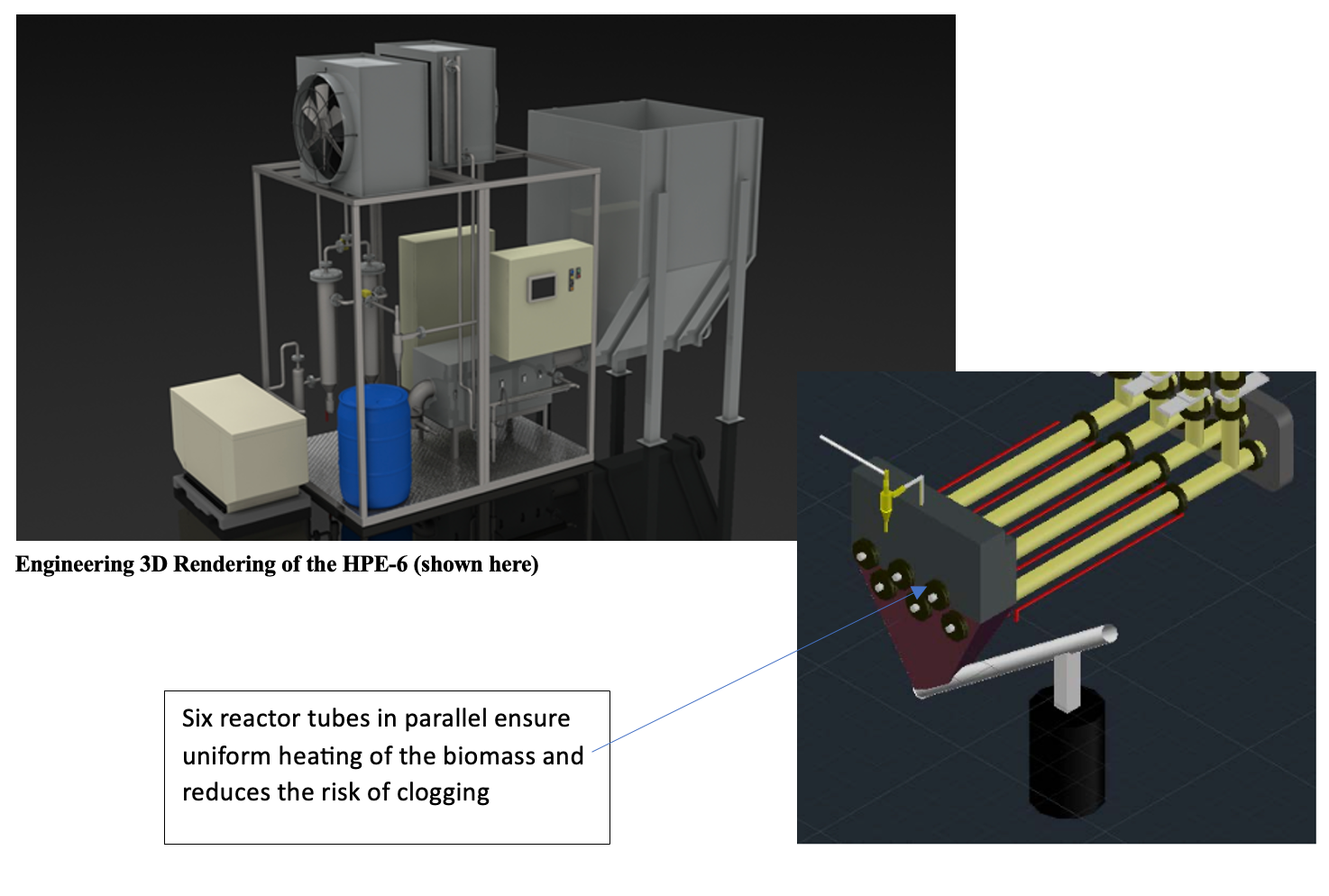

The Bi-Modular Reactor HPe-6 system by HiPoint Energy is designed to convert different types of green waste into high-yield syngas or biodiesel and biochar. Based on preliminary calculations by HPE, This proposed system will consist of six reactors running in parallel, processing 9 million pounds of input feedstock annually. This will make it capable of producing 2 tons of biochar and 12 tons of syngas or biodiesel per day. HPE expects the system to be cost-effective and generate revenue from selling 67,000 bags of biochar and 4,380 tons (10,000 KWh) of syngas. The system is designed for low operational and maintenance costs, allowing for an FTS potential return on investment within three years.

Volumes

The Bi-Modular Reactor HPe-6 system by HiPoint Energy is designed to convert different types of green waste into high-yield syngas or biodiesel and biochar. Based on preliminary calculations by HPE, This proposed system will consist of six reactors running in parallel, processing 9 million pounds of input feedstock annually. This will make it capable of producing 2 tons of biochar and 12 tons of syngas or biodiesel per day. HPE expects the system to be cost-effective and generate revenue from selling 67,000 bags of biochar and 4,380 tons (10,000 KWh) of syngas. The system is designed for low operational and maintenance costs, allowing for an FTS potential return on investment within three years.