Process

Indirectly Heated Pyrolytic Gasification (IHPG)

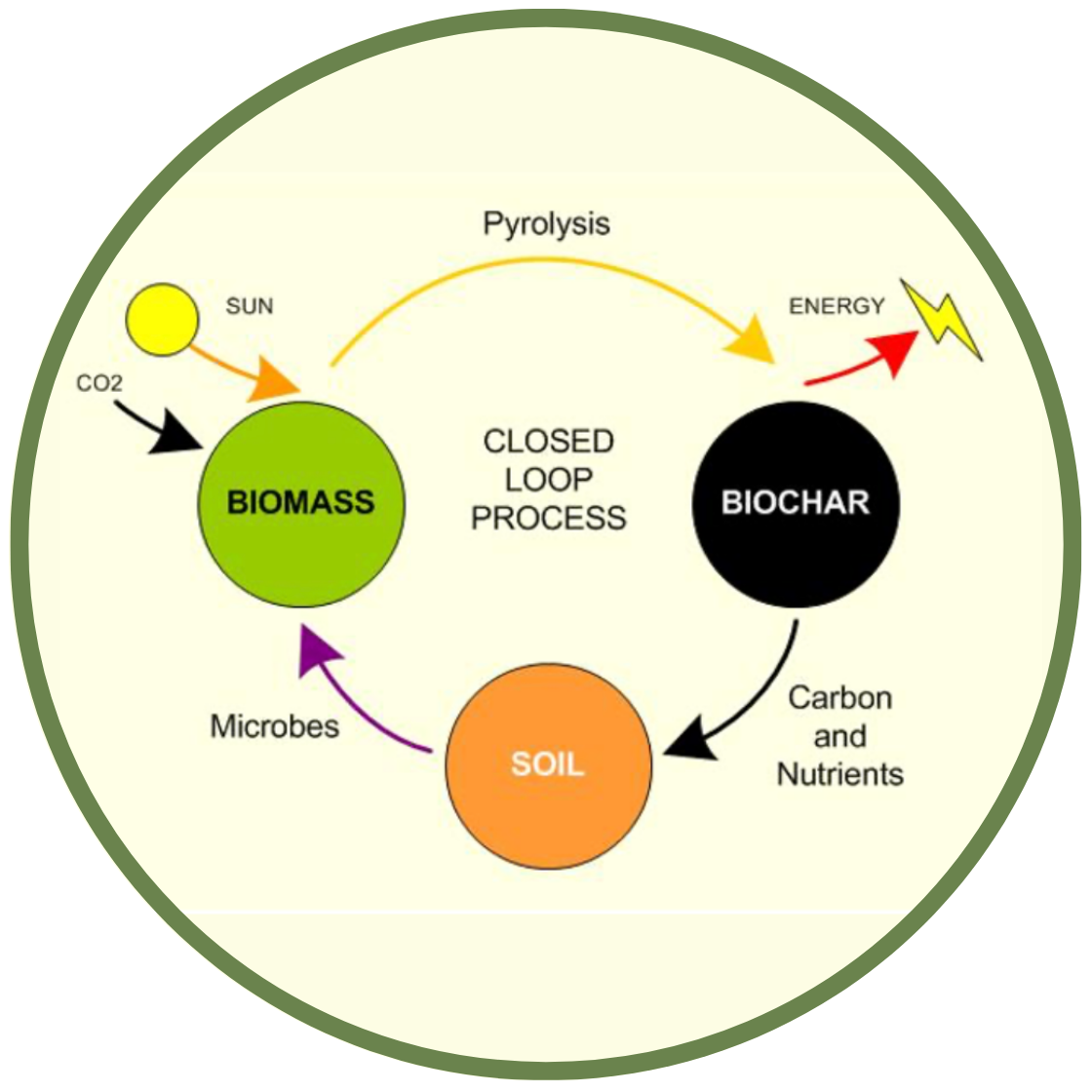

Unlike many industrial “green” technologies that require vast new land footprints or disrupt natural habitats, HiPoint Energy's IHPG-based unit operates entirely within the waste footprint. Its impact is regenerative, not extractive. The symmetry is clear: waste in → clean fuel + regenerative carbon out. This circularity strengthens soil microbiomes, increases cation-exchange capacity, and locks atmospheric carbon into non-labile form for centuries.

Feedstock

The ideal feedstock is plant-based lignocellulosic (woody) material such as agricultural residue, landscape trimmings, cannabis waste, disaster relief cleanup, cardboard, and non-halogenated plastics. By integrating these innovations, the feedstock mix can be suitable for warehouses, office buildings, farm operations, forward operating bases, and remote facilities.

Cannabis Hemp Waste

Agricultural Crop Waste

Disaster Relief Waste

Community Yard Waste

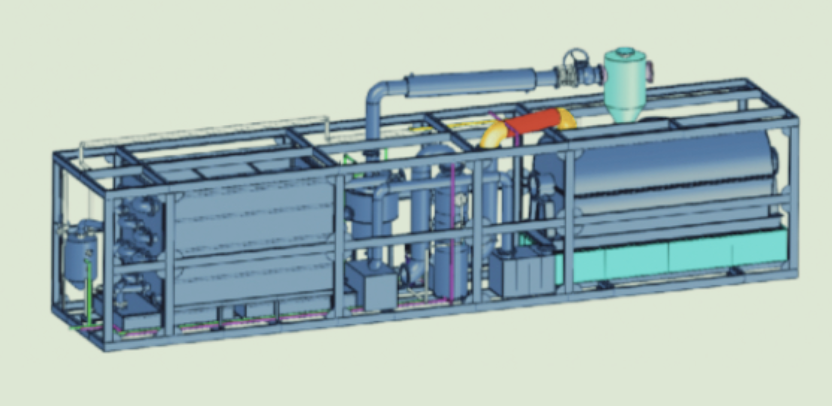

HPE is adapting an innovative biomass conversion system that transforms organic matter into valuable by-products. The technology stands out from existing solutions due to its Indirectly- Heated Pyrolytic Gasification process. This high-temperature process breaks down all complex hydrocarbons into their simplest components to produce a liquid that is distilled into alternative diesel, along with a pure carbon biochar residue. The system is designed at this stage to produce alternative diesel instead of syngas or other forms of biofuel due to the low-cost production and high efficiency. It can also be fed through a membrane separation unit to extract a portion of the hydrogen. Because the technology is energy self-sufficient when provided a steady input of feedstock, this “green” hydrogen is radically less expensive than competing methods.

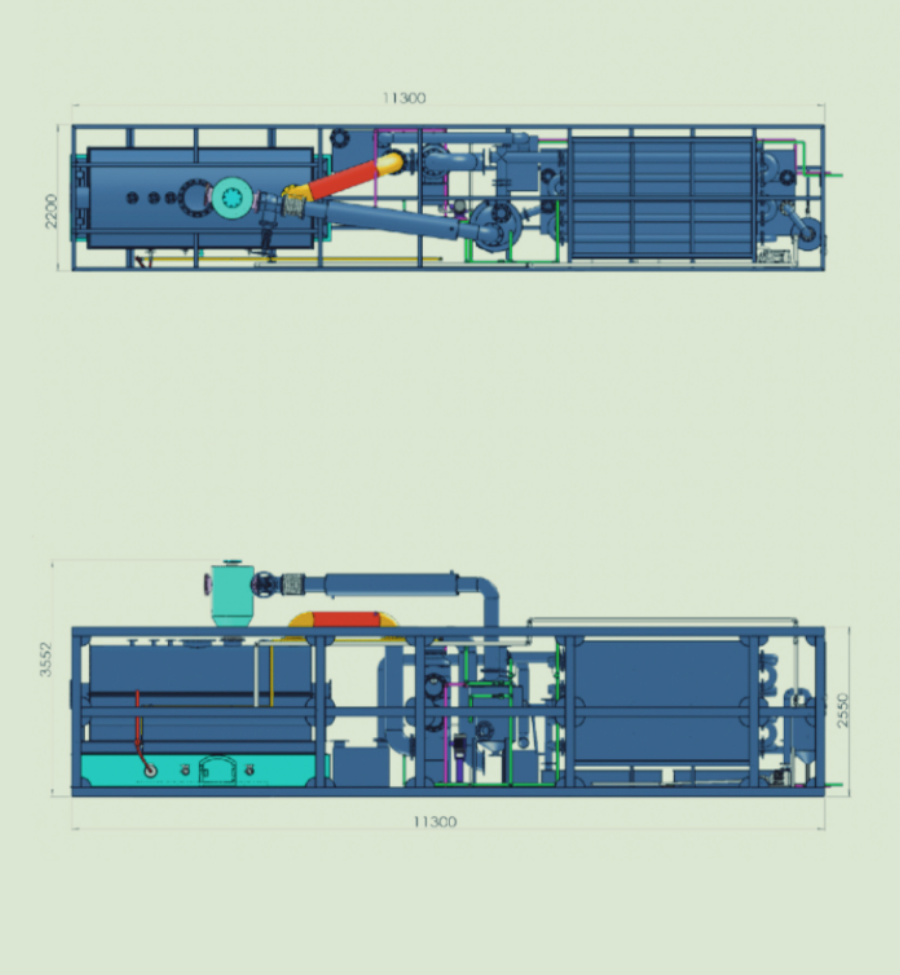

Volume

The HPe-6 system by HiPoint Energy is designed to convert various types of green waste into high-yield alternative diesel and biochar. Each HPE reactor system is designed to process 3 tons of input waste per day and can be daisy-chained with additional reactor units to increase the volume. Each 3-ton reactor can produce 150 gallons of alt-diesel (equivalent to 2,00 kWh of electricity) and one ton of biochar per day. The choice of input feedstock material will change the volumes of output.